Plywood is a versatile building material that is widely used in construction, furniture making, and other applications. When considering plywood for a project, it’s essential to understand its sizes and prices. This article will provide a comprehensive guide to help you navigate the world of plywood dimensions and costs.

Type of plywood

Plywood is a type of engineered wood product that is made by bonding together several layers or plies of thin wood veneers. These veneers are typically obtained from hardwood or softwood logs. Plywood is known for its strength, durability, and versatility, and it is widely used in construction, furniture manufacturing, and various other applications.

There are several types of plywood available, each designed to suit specific purposes. Here are some common types:

- Softwood Plywood: This type of plywood is made from softwood veneers, such as pine, fir, or cedar. Softwood plywood is often used in construction projects, such as roof sheathing, flooring, and wall panels.

- Hardwood Plywood: Hardwood plywood is made from hardwood veneers, such as oak, birch, or maple. It is commonly used in furniture manufacturing, cabinetry, and architectural woodworking.

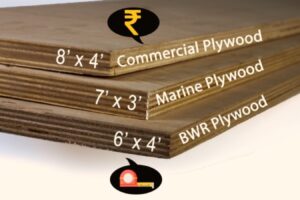

- Marine Plywood: Marine plywood is specifically designed for use in humid or wet environments, such as boat construction or outdoor structures. It is made with waterproof glue and is highly resistant to moisture.

- Exterior Plywood: Exterior plywood is treated with preservatives to enhance its resistance to moisture, making it suitable for outdoor applications like siding, sheds, and fences.

- Interior Plywood: Interior plywood is not designed for exposure to moisture or outdoor conditions. It is commonly used for interior applications like cabinets, shelves, and decorative paneling.

- Structural Plywood: Structural plywood is manufactured to meet specific strength and stiffness requirements. It is commonly used in applications where load-bearing capacity is crucial, such as beams, joists, and subflooring.

- Fire-Rated Plywood: Fire-rated plywood is treated with fire-resistant chemicals and is used in buildings where fire safety regulations must be met.

- Marine-Grade Plywood:Marine-grade plywood refers to a specific type of plywood that is designed and manufactured for use in marine environments, particularly in boat construction and other applications that involve exposure to water and moisture. It is built to withstand the challenging conditions of marine settings, including high humidity, water exposure, and saltwater corrosion.

These are just a few examples of the many types of plywood available. The selection of plywood depends on the specific requirements of the project, including the desired strength, durability, moisture resistance, and appearance.

How Much Does Plywood Cost?

The cost of plywood can vary widely depending on several factors such as the grade, thickness, type of wood, and your location. Additionally, market conditions and supplier pricing policies can also affect the cost.

To give you a general idea, as of my knowledge cutoff in September 2021, the price range for a standard 4 feet by 8 feet (1.22 meters by 2.44 meters) sheet of plywood can be between $10 to $50 USD, depending on the factors mentioned above. Higher quality plywood made from hardwood or specialty veneers can be more expensive.

However, it’s important to note that these prices are subject to change, and it’s always best to check with local suppliers or visit a nearby hardware store to get accurate and up-to-date pricing information for plywood in your area.

Why plywood are expensive?

Plywood can be more expensive compared to other wood-based materials or alternatives for several reasons:

- Manufacturing Process: Plywood is made by layering thin sheets of wood veneer together with adhesive. This manufacturing process requires precise machinery, skilled labor, and quality control measures, which can contribute to higher production costs.

- Raw Material Costs: The cost of the raw materials used in plywood production, such as the wood veneer, can vary depending on the type and quality of wood used. Hardwood veneers, for example, tend to be more expensive than softwood veneers.

- Quality and Grade: Plywood is available in various grades, such as A, B, C, and D, with A being the highest quality. Higher-grade plywood typically has fewer defects, better visual appeal, and improved structural integrity, but it also tends to be more expensive.

- Specialty Plywood: Certain types of plywood, such as marine plywood or fire-resistant plywood, are designed for specific applications and undergo additional treatments or feature specialized properties. These specialty types of plywood often come at a higher cost due to their unique characteristics.

- Market Demand and Supply: Plywood prices can also be influenced by market demand and supply dynamics. Factors like global wood availability, lumber market conditions, and transportation costs can affect the price of plywood.

It’s worth noting that the price of plywood can fluctuate over time due to changes in these factors. It’s always best to check with local suppliers or visit a nearby hardware store to get the most accurate and up-to-date pricing information for plywood in your area.

When will plywood prices go down?

Plywood prices can be influenced by various factors, including supply and demand dynamics, raw material costs, economic conditions, and other market forces.

Historically, plywood prices have been known to fluctuate over time. Factors such as changes in lumber prices, availability of raw materials, and market conditions can impact plywood pricing. Therefore, it’s challenging to predict precisely when plywood prices will go down.

To stay informed about plywood prices and potential market trends, it’s advisable to keep track of industry news, follow updates from plywood manufacturers or suppliers, and consult with local experts or professionals in the construction and woodworking industries. They may have better insights into regional or local market trends that could affect plywood prices in your area.

Understanding Plywood Size

Plywood Definition: Plywood is a composite material made up of thin wood veneers glued together in layers. It offers strength, durability, and stability, making it a popular choice for various projects.

Non-Standard Plywood Sizes: In addition to standard sizes, plywood is also available in non-standard dimensions. These non-standard sizes cater to specific applications or custom projects. For instance, specialty plywood sheets may be designed for curved surfaces or larger structural elements.

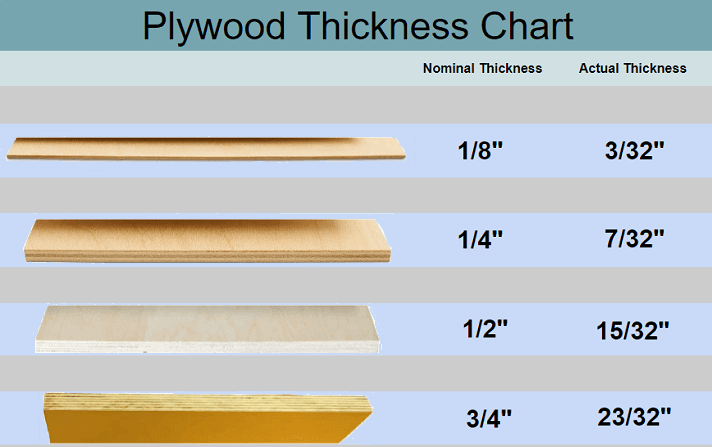

Understanding Plywood Thickness: Plywood thickness is an important consideration, as it determines its strength and suitability for different projects. Thicker plywood is generally sturdier and better suited for applications where load-bearing capacity is crucial, such as flooring or roofing.

Plywood Size Conversion: Converting plywood sizes between metric and imperial measurements can be useful. For example, if you need to convert 4×8 feet plywood to metric measurements, it would be approximately 1220mm x 2440mm. Online resources and conversion calculators can help with this process.

Factors Affecting Plywood Size Selection: When selecting plywood sizes, several factors should be taken into account. Consider the project requirements, structural needs, and transportation limitations. Smaller plywood sizes are easier to handle and transport, while larger sheets minimize seams and joints, providing a more seamless appearance.

Why Learn About Plywood Sizes?

Learning about plywood sizes can be beneficial for several reasons:

- Project Planning: Understanding plywood sizes allows you to plan your construction or woodworking projects more effectively. You can accurately estimate the number of sheets required, calculate the total area coverage, and optimize material usage, thereby minimizing waste and cost.

- Material Selection: Different projects may require specific plywood sizes based on their intended use and structural requirements. Being knowledgeable about plywood sizes enables you to choose the appropriate sheet dimensions that align with your project needs, ensuring structural integrity and performance.

- Compatibility: Plywood sizes can influence compatibility with other building materials and components. By knowing the standard sizes, you can ensure that the plywood you select fits well with other materials and integrates smoothly into your project design.

- Cost Estimation: Understanding plywood sizes helps in estimating the cost of materials accurately. By knowing the dimensions of plywood sheets, you can calculate the required quantity and calculate the overall cost based on prevailing prices, assisting in budgeting and cost management.

- Communication: If you collaborate with professionals, contractors, or suppliers, having knowledge of plywood sizes allows for effective communication. You can clearly express your requirements, discuss project details, and ensure that everyone involved is on the same page regarding the dimensions and specifications of the plywood needed.

Overall, learning about plywood sizes enhances your ability to plan, select materials, estimate costs, and communicate effectively, contributing to the successful execution of your projects.

Exploring Plywood Prices

- Plywood Price Overview: Plywood cost can vary based on several factors. These include the plywood grade, quality, and market conditions. The grades of plywood, such as CDX, ACX, and marine-grade, differ in terms of their construction, durability, and intended applications. Higher-grade plywood typically commands a higher price due to its superior quality.

- Average Plywood Prices: The average plywood cost depend on factors like size, thickness, and quality. For example, CDX grade plywood, commonly used for construction purposes, may range from $30 to $50 per sheet for a 4×8 feet dimension. ACX grade plywood, known for its smoother finish, can cost anywhere between $40 to $70 per sheet. Marine-grade plywood, suitable for moisture-prone areas, is generally more expensive and may range from $70 to $100 per sheet.

- Factors Affecting Plywood Prices: Several factors influence plywood prices. The grade, quality, and veneer type impact the overall cost. The location of the supplier can also play a role, as shipping costs may vary. Additionally, market demand and availability can lead to price fluctuations. It’s important to consider these factors when budgeting for your project.

People Also Ask FAQs

Here are some frequently asked questions related to plywood sizes and prices:

- Q: What are the most common plywood sheet sizes?

- A: The most common plywood sheet sizes are 4×8 feet, 4×10 feet, and 5×10 feet.

- Q: How thick is plywood typically used for furniture making?

- A: Plywood thickness used for furniture making can vary, but 3/4 inch and 1/2 inch thicknesses are commonly used.

- Q: Does plywood size affect its price?

- A: Plywood size can affect its price, with larger sheets generally costing more due to increased material and production costs.

- Q: What is the price difference between CDX and marine-grade plywood?

- A: Marine-grade plywood is generally more expensive than CDX plywood due to its enhanced water resistance and durability.

- Q: Are non-standard plywood sizes readily available?

- A: Non-standard plywood sizes may be available, but they are often less common and may require special ordering or customization.

- Q: How does plywood quality impact its price?

- A: Higher-quality plywood, which exhibits better construction and finish, typically commands a higher price.

Conclusion

In conclusion, understanding the sizes and prices of plywood is crucial for any project involving this versatile material. By considering the standard and non-standard sizes, plywood thicknesses, and factors affecting prices, you can make informed decisions and ensure the success of your endeavors.

Note: The prices mentioned in this article are approximate and may vary based on location, supplier, and market conditions. It’s always recommended to check with local suppliers for the most accurate pricing information.