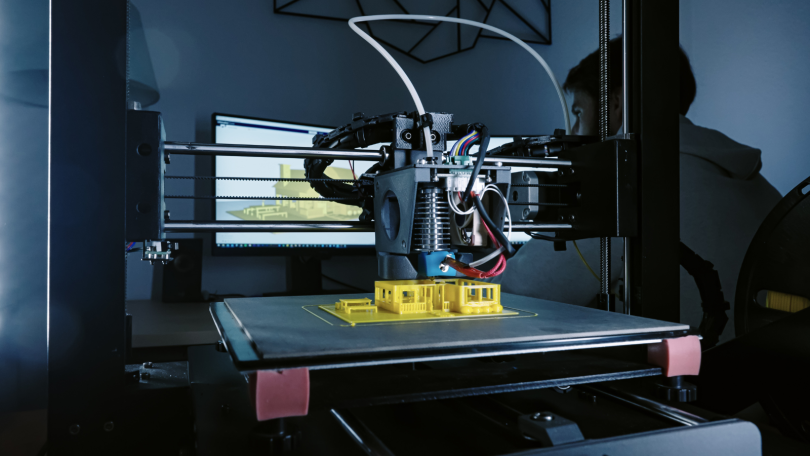

In the fast-developing world of construction, the appearance of advanced 3D concrete printing equipment stands as a technical genius, transforming the way we build. This troublemaking technology possibilities redefine efficiency, lower labor costs, and offer supreme design freedom. It is a beacon for the industry’s future, drawing the gaze of construction professionals, civil engineers, and architects alike.

3D concrete printing is akin to a high-precision sculptor, albeit on a larger-than-life scale. It extrudes layers of concrete with remarkable accuracy, following digital designs to the millimeter. The process is not only faster than traditional construction methods; it also opens doors to architectural feats previously unattainable. I am here to shed light on the myriad of benefits this equipment brings and how it is reshaping the construction landscape.

Benefits of Advanced 3D Concrete Printing Equipment

Speed and Precision

Gone are the days when intricate concrete structures were painstakingly laid by hand. Advanced 3D concrete printing machines execute plans with astonishing speed and exceptional detail. Lay times for walls and structural components are slashed, and software-guided arms move with machine-like consistency to create flawless geometric shapes. The precision offered by this technology is not just a luxury; it is a necessity in constructing the kind of intricately designed buildings that 3D printing has made possible.

Cost-effectiveness

The initial investment in 3D concrete printing technology is a significant business decision, but it is swiftly justified by the bottom line. Reductions in labor costs minimized material waste, and increased project turnaround all contribute to a compelling financial case for its adoption. Factor in the ability to directly print on-site, and the economic proposition becomes even more convincing.

Design Flexibility

3D concrete printing is a game-changer for architects and designers. No longer limited by the limitations of old-style formwork, 3D printing allows for the understanding of almost any design, however complex or brave. The ability to create custom, one-off pieces reduces design compromises and can lead to structures that are both beautifully attractive and architecturally sound.

Applications in Construction

The scope of 3D concrete printing’s applications is vast, spanning from residential builds to large-scale infrastructure.

High-rise Buildings

In the empire of high-rise construction, 3D printing’s benefits are especially marked. The ability to produce assembled elements on site, such as facades and detailed architectural features, updates the building process. When every minute saved translates to lower costs and earlier occupancy, it is clear why high-rise developers are eyeing this technology.

Customized Structures

3D concrete printing lends itself to customization. Whether it is tailoring a structure to fit a unique plot or meeting the exacting design requirements of a private villa, the versatility of the equipment allows for a bespoke approach that would be prohibitively expensive using traditional methods.

Infrastructure Projects

When infrastructure projects involve repetitive units like piers, bridges, and culverts, 3D concrete printing can offer standardized precision at a scale unthinkable with manual labor. The technology’s automation ensures that each unit meets specifications consistently, ensuring durability and safety.

Case Studies

To illustrate the tangible impact of 3D concrete printing, consider the Marina Bay Sands expansion in Singapore, where 3D printing technology was used to craft complex structural elements. The project saw a significant reduction in labor requirements, an accelerated pace of construction, and an overall reduction in material costs the trifecta of efficiency as far as construction projects are concerned.

Another compelling case is the 3D printed office in Dubai, the first 3D printed building of its measure. The project not only broke new ground in architectural innovation but did so with a 50% reduction in total labor costs and a 60% reduction in waste.

Considerations for Implementation

The adoption of 3D concrete printing is not without its challenges, and careful considerations must be made before integrating this technology into any construction operation.

Training and Expertise

Today’s construction professionals must become tomorrow’s digital fabricators. Passable training in operating and maintaining 3D concrete printing equipment is important. This shift in skillset represents a significant change in the labor market, highlighting the need for ongoing education and upskilling within the industry.

Maintenance Requirements

The sophistication of 3D concrete printing machinery demands rigorous maintenance schedules. Regular equipment checks and software updates are critical to ensure projects proceed without interruptions. Collaboration with equipment manufacturers to establish maintenance best practices is prudent.

Regulatory Compliance

The innovation of 3D concrete printing raises numerous regulatory questions. From building codes to material specifications, the industry and its regulators will need to work closely to develop standards that ensure the safety and strength of 3D printed structures. Remaining up-to-date on emerging rules and contributing to correction efforts can help minimize legal and obedience risks.

Conclusion

The horizon for 3D concrete printing equipment in construction is vast and promising. It offers a path to more sustainable, efficient, and tailored building practices. While challenges exist in the current landscape, they are opportunities for industry players to innovate and improve.

The technology’s current applications hint at a future where entire city skylines could be imaginatively and frugally printed in concrete. Until then, the gradual integration of 3D concrete printing into the fabric of construction practices will continue to captivate the industry’s pioneers and those who dare to dream big.